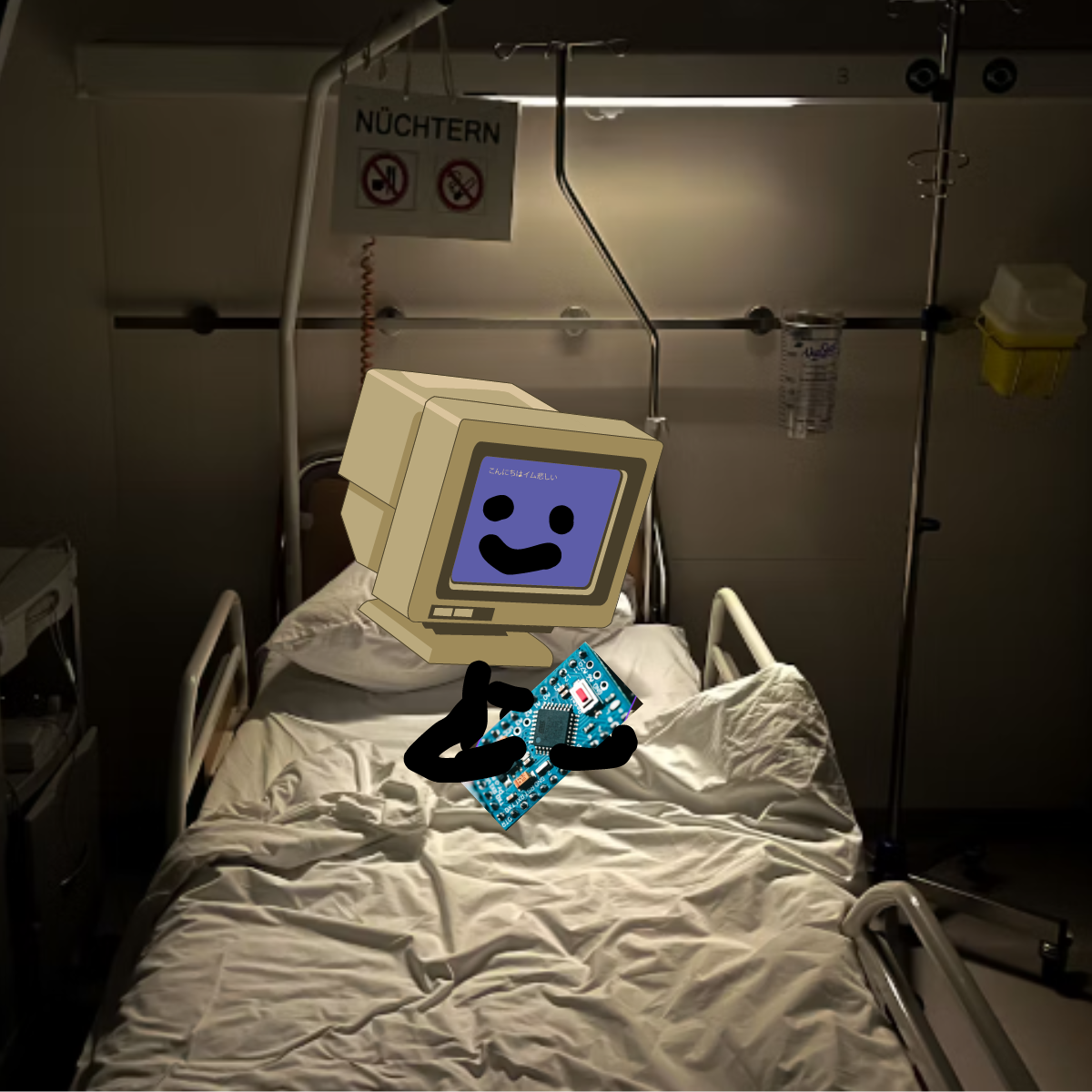

how are circuit boards born?

They're tiny, they're delicate, they're sensitive to microscopic misalignments...how do we make these things?

It's mind boggling to me that circuit boards can be manufactured quickly enough to be economical. Look at all of the stuff on that board! It's tiny, delicate, sensitive to microscopic misalignments...how do we make these things?

The journey from idea to part starts with engineering (as you might expect). The engineer designs the PCB and creates a Gerber file.

The Gerber file includes machine-readable definition of:

- PCB size

- Number of layers

- Conductors in each layers

- Components and location

Then the boards go to manufacturers (like Aurora Boardworks) to get built. First, they're cut to size and solder paste gets applied to create the connection points for all of the parts which will be attached to the board.

If more than 50 boards are being made at once, this is usually done via a screen printing process. It adds a little lead time to create the screens used to apply the paste, but once they're complete the cycle time is only about 15 seconds per board!

If the volumes are lower than 50, a jet printer is used to lay down the solder paste. The machine used to do this is similar to an inkjet printer. The solder has significant mass so these machines actually use the same calculations that military bombers use to determine where the payload of solder will land on the board! Only difference, the payloads can be as small as 30 microns! The cycle time for a board made this way is only about a minute.

..these machines actually use the same calculations that military bombers use to determine where the payload of solder will land.

This is what is so fascinating to me about this manufacturing process. I mean, look at a circuit board. There are a bazillion tiny little specks of solder on each layer, but they take only a few minutes to create. Mind blown.

This is only the beginning of the magic though. The thing that got me interested in this whole process in the first place is the pick and place machines used to accurately locate each of the thousands of tiny components. I assumed the machines doing this would have to do it quickly in order to be economical. What I did not expect is that "quickly" would mean 24,000 components per hour! That means that every single second the machine is precisely locating no less than 6 components, most of which are smaller than ants! Mind blown again.

every single second the machine is precisely locating no less than 6 components, most of which are smaller than ants!

The machine takes a photo of each component as it comes off the reel, makes the minute adjustments required based on the incoming orientation and machine gun fires them onto the boards.

Once all of the components are in place they're baked onto the solder dots on the board in a 400+ degree F oven and sent out for inspection and test.

The speed at which these unbelievably complex assemblies come off the line is mind boggling! Very few people understand the level of manufacturing sophistication to build all of the stuff we take for granted.

Thanks to Daniel and Aurora Boardworks for helping me understand this process!